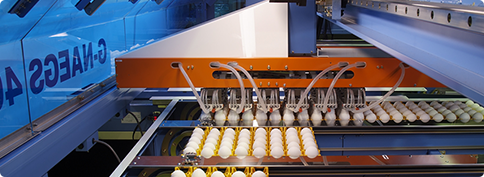

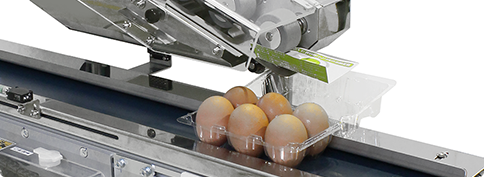

Pack eggs

around the world

with NABEL's machine!

around the world

with NABEL's machine!

News

Exhibition News

《Upcoming》Middle East Poultry Expo 2024

Exhibition News

《Upcoming》PEAK2024

Exhibition News

《Upcoming》International Poultry & Pig Show (IPPS JAPAN) 2024

Exhibition News

《Upcoming》The International Farmer Summit 2024

Exhibition News

《Upcoming》International Production & Processing Expo 2024

News

【New release】Compact Farm Packer Sakura100

News

【New release】A Cloud System for Egg Quality Management KENZO

News

We are on social media now!

News

New Year CEO Message

News

Digital Egg Tester DET6500 was used to select the Ministry of Agriculture, Forestry and Fisheries’ Award.

Exhibition News

《Upcoming》Middle East Poultry Expo 2024

Exhibition News

《Upcoming》PEAK2024

Exhibition News

《Upcoming》International Poultry & Pig Show (IPPS JAPAN) 2024

Exhibition News

《Upcoming》The International Farmer Summit 2024

Exhibition News

《Upcoming》International Production & Processing Expo 2024

Company

Your satisfaction is

our pleasure.

our pleasure.

One can achieve a sense of fulfillment when he is appreciated by others.

NABEL as a manufacuturing company shall continue to be sincere for the future.

NABEL as a manufacuturing company shall continue to be sincere for the future.